How to Wind Perfect Coilgun Coils

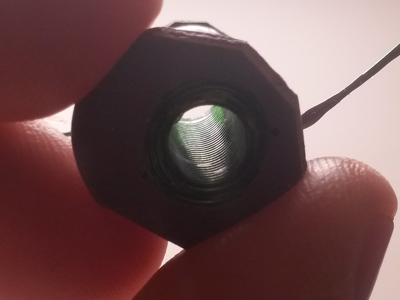

You can see here how the epoxy sagged a little bit.

You can see here how the epoxy sagged a little bit.It's still going to work, but I know from past experience that if you leave the coil rotating all night it will cure with a perfect smooth shape.

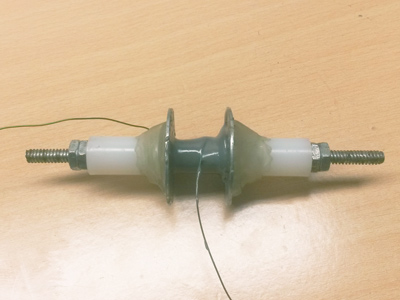

Once you remove the threaded rod, the washers should break off with with only a little bit of wiggling.

Once you remove the threaded rod, the washers should break off with with only a little bit of wiggling. Now's also a good time to trim the flash.

Now's also a good time to trim the flash.Also, it's not pictured but you may want to apply a drop of glue (or more epoxy) to the top of the coil where the wire escapes. If you do that, let it harden before continuing.

Time to press out the mandrel.

Time to press out the mandrel.To do this, I use a rod that's slightly smaller than the mandrel, but not small enough to fit inside. I ground the end down to act as a guide.

Ok, now use your arbour press to push the mandrel out.

Ok, now use your arbour press to push the mandrel out.Or a old rusty bar clamp...

(There's a hole drilled in the wood block to accept the mandrel.)